About AutoCast

AutoCAST provides a complete solution for casting methods design, with advanced simulation and complete optimization.

Part Analysis

• Geometric and mass properties

• Sectional thickness analysis

• Cored feature recognition

Mold Cavity Design

• Part orientation, stepped parting line

• Horizontal and vertical molding

• Core and print design, plug drilled hole

• Mold size and multi-cavity layout

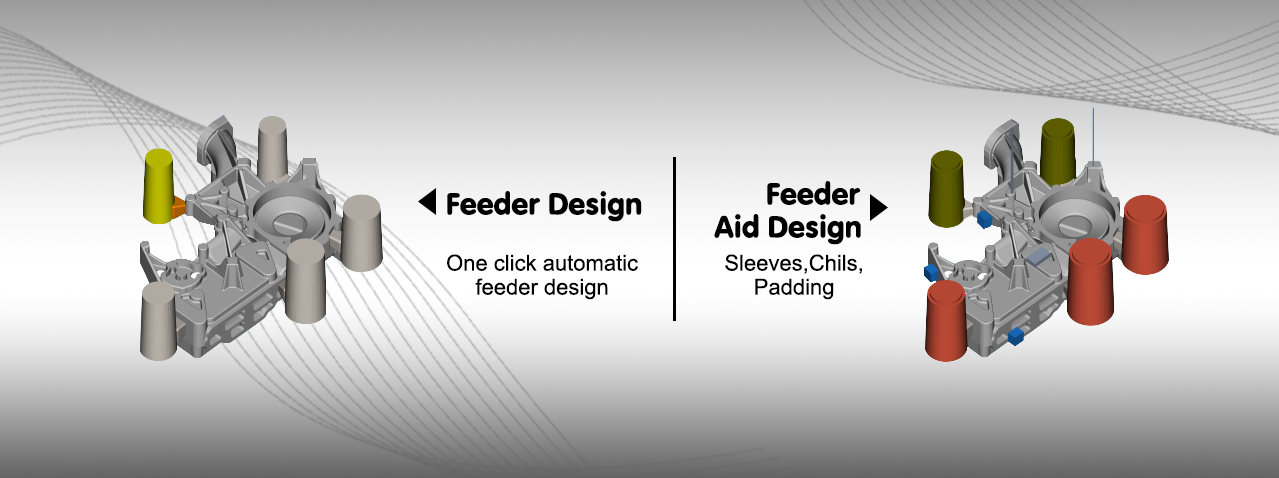

Feeder Design & Optimization

• Hotspot location; Feeder design

• Feedaids: Neck down sleeve, chill, padding

• Directional solidification: feed-paths

• Automatic feeder size optimization

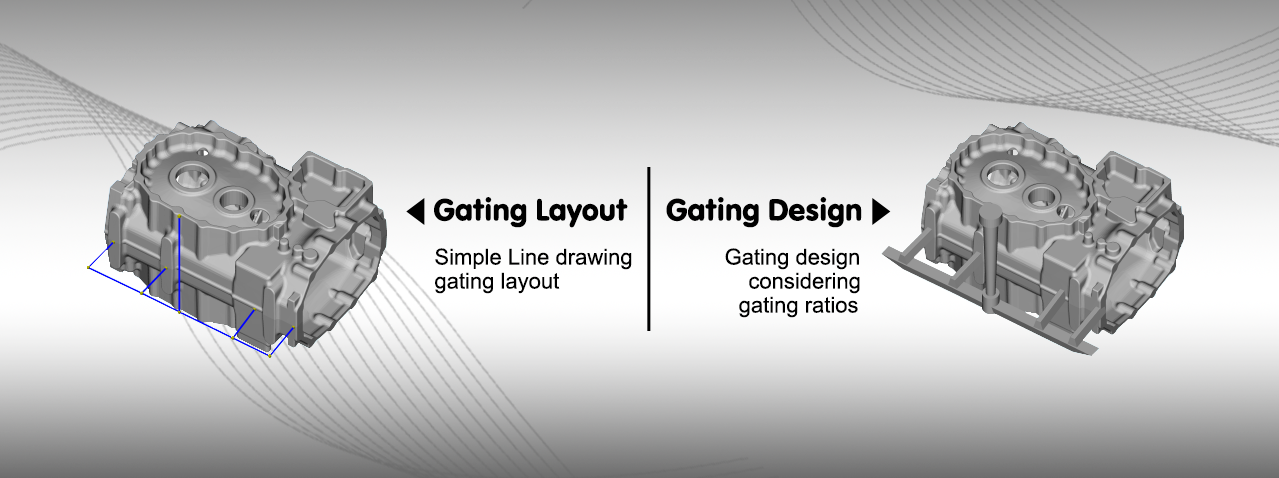

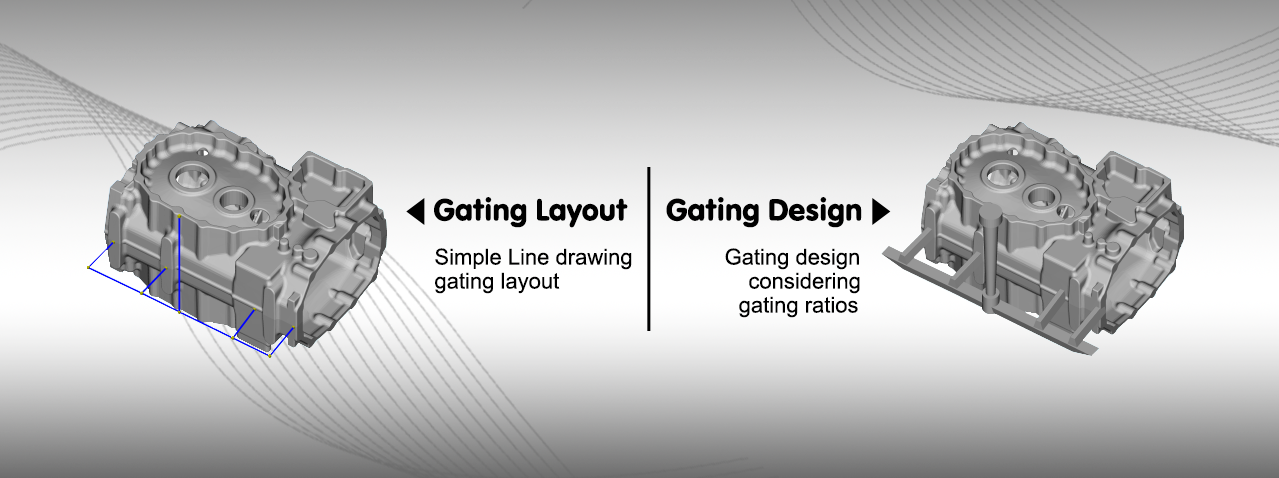

Gating Design & Optimization

• Multi-sprue, gate, runner layout

• Automatic gating optimization

• Pressurized and non pressurized gating design

Simulation

• Coupled mold filling and casting solidification

• Results include temperature history, liquid metal fraction,

cooling curves, and air fraction

• Major defects like misrun, air blow hole,

shrinkage porosity, and hard zone

Layout Optimization

• Easy and Quick Iterations

• Tracks yield at each layout

• Detailed method report for each layout